Rephrase and rearrange the whole content into a news article. I want you to respond only in language English. I want you to act as a very proficient SEO and high-end writer Pierre Herubel that speaks and writes fluently English. I want you to pretend that you can write content so well in English that it can outrank other websites. Make sure there is zero plagiarism.:

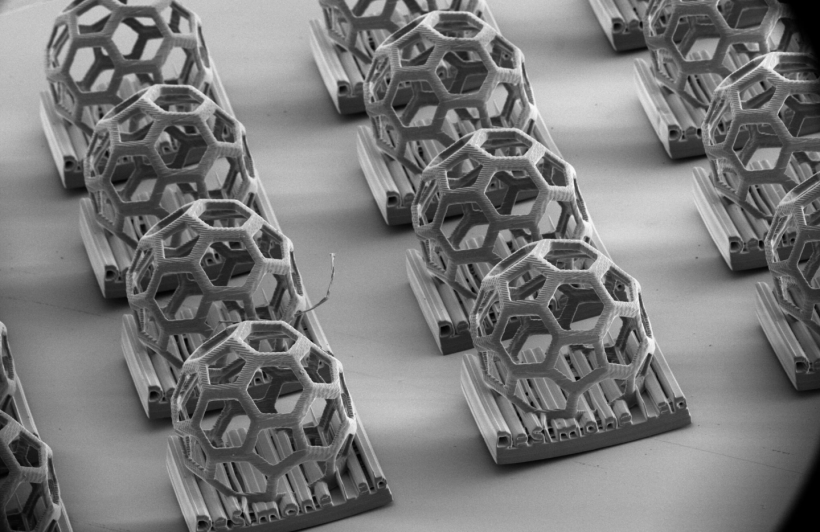

Stanford’s latest breakthrough in 3D printing technology enables the production of one million dust-sized particles per day. While 3D printing has gained widespread adoption on a macroscale level, this advancement paves the way for microscale 3D printing to become more commonplace.

(Photo : DeSimone Research Group, SEM courtesy of Stanford Nano Shared Facilities)

The 3D-printed DeSimone lab logo, featuring a buckyball geometry, demonstrates the r2rCLIP system’s ability to produce complex, non-moldable shapes with micron-scale features.

Unveiling New 3D Printing Technique

Researchers from Stanford University have unveiled a groundbreaking technique in 3D printing, enabling the production of up to one million microscale particles daily.

These minute particles, resembling dust particles to the naked eye, boast intricate detailing and offer versatility for various applications, including microfluidics, vaccine delivery, and microelectronics, as per a recent press release.

While 3D printing, or additive manufacturing, has flourished in producing consumer goods like shoes, hearing aids, and household items on a macroscale level, this innovation opens doors to microscale manufacturing.

Traditionally, achieving high-resolution output at microscopic scales necessitated compromising production speed, but this new method addresses this limitation.

Under the leadership of Joseph DeSimone, a professor of Translational Medicine at Stanford University, a research group has been pioneering a scalable method for microscale 3D printing known as continuous liquid interface production (CLIP).

Their latest breakthrough involves the establishment of an industrial-scale model for 3D printing microparticles, signaling a significant advancement in microscale manufacturing.

Utilizing UV Light

CLIP utilizes UV light to swiftly solidify resin into desired forms. Thisinvolves an oxygen-permeable window positioned above the UV light projector, serving as a “dead-zone” to prevent resin from adhering to the window while enabling precise features to be solidified onto the particle.

In their recent research endeavors, the team has established a roll-to-roll setup to facilitate the mass production of intricately shaped particles significantly smaller than a human hair. This setup entails a meticulously tensioned film being fed into the CLIP printer, where customizable shapes are printed.

Subsequently, the film undergoes various processes, including washing, solidification, and extraction of the shapes on an assembly line.

Termed roll-to-roll CLIP (r2rCLIP), this innovative method allows the emptied film to be rolled back up after the completion of the production process.

Also Read: Chameleon Inspired 3D-printing Ink Changes Colors in a Single Print Job

In contrast to the traditional method, which requires the painstaking and time-consuming individual removal of printed particle batches, r2rCLIP boasts the capability to produce a million particles daily.

Joseph DeSimone, head of the lab, emphasized the significance of their focus on translational manufacturing science. He stated in the press release their laboratory is dedicated to developing tools that facilitate scalability. This achievement exemplifies the impact of that focus.

Representing a significant advancement in 3D printing, the development of r2rCLIP is poised to revolutionize various industries.

Joseph DeSimone, the lead researcher, noted that this innovation marks a transition from solely focusing on the printing process to exploring the vast potential applications of 3D products themselves.

He emphasized that while r2rCLIP lays the foundation for transformative technology, the next phase involves identifying high-value applications for this groundbreaking approach.

Related Article: China-US Scientists Unveil World’s Strongest 3D-Printed Titanium Alloy

ⓒ 2024 TECHTIMES.com All rights reserved. Do not reproduce without permission.